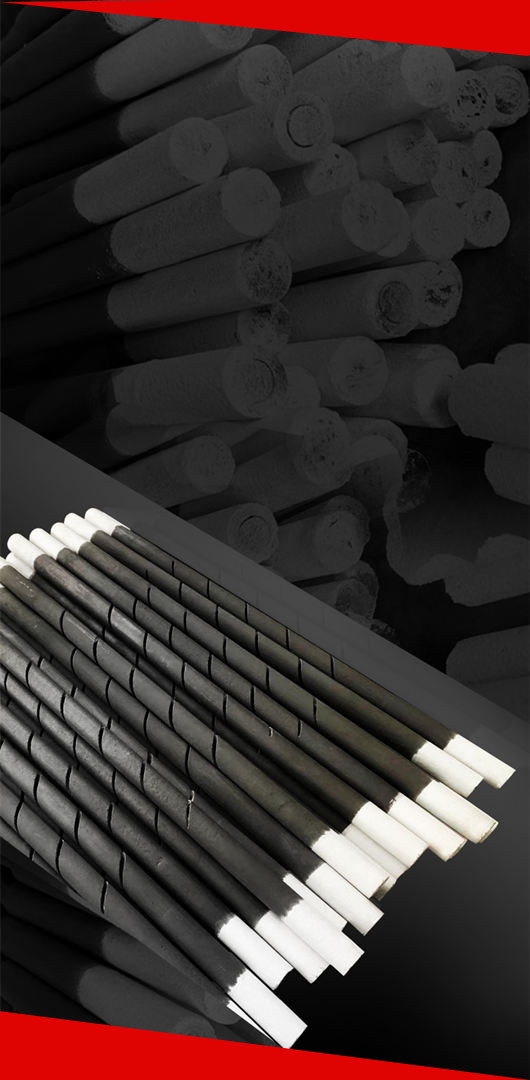

Silicon Carbide Rod Type SG are widely used in high temperature fields such as electronics, powder metallurgy, ceramics, glass, semiconductors, etc.

Product category

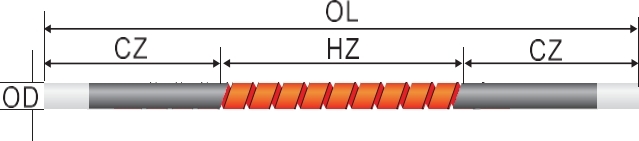

SIC heating ElementsEssential information

1

info@hnlasting.com Leave Message

One-Stop Service For SIC&MoSi2 Heating Elements

Contact Now!For any inquire, quality feedback or technical question, there always be a professional responding answered by our technician team within 24 hours.